By utilizing 100% virgin raw materials for our high-strength PET straps and conducting rigorous testing in NABL-accredited laboratories, we ensure superior quality that stands out against competitors.

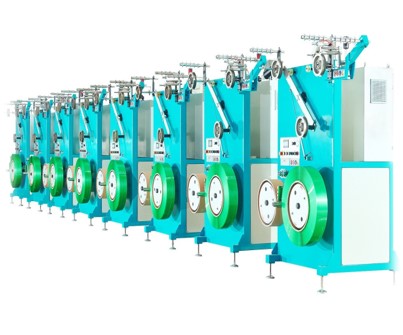

PET Polyester Strap is manufactured from Polythene Terephthalate material. It is the best and environment-friendly substitute of steel or chain strap and is used with automatic or semi-automatic battery tools. Our manufacturing plants used virgin material PET strapping as well as post-consumer and post-industrial PET containers to make new strapping. Requiring substantially fewer raw materials to manufacture than other strapping, CNIP innovative composition enables larger coils of strap, resulting in up to 40% less packaging waste and lower transportation costs.

The strap used for density bales pressed in a 20-21 inch wide by 54-55 inch long press box should typically measure between 87 to 89 inches in length, although it may extend up to 90 to 95 inches depending on the specific dimensions of the press box.

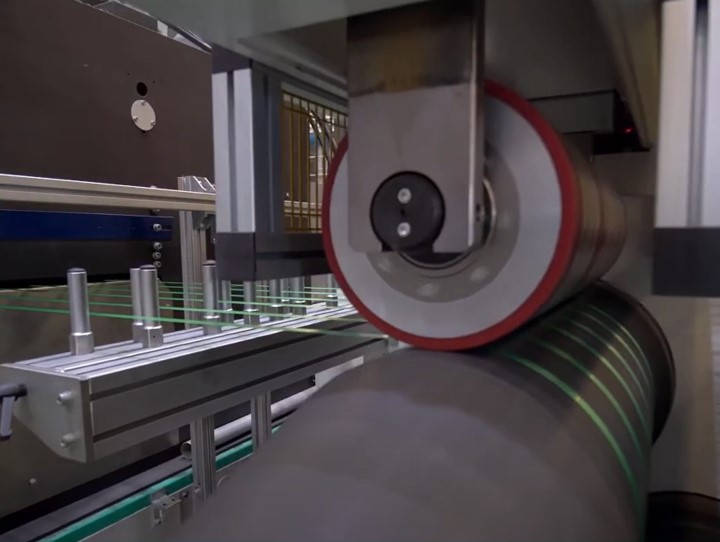

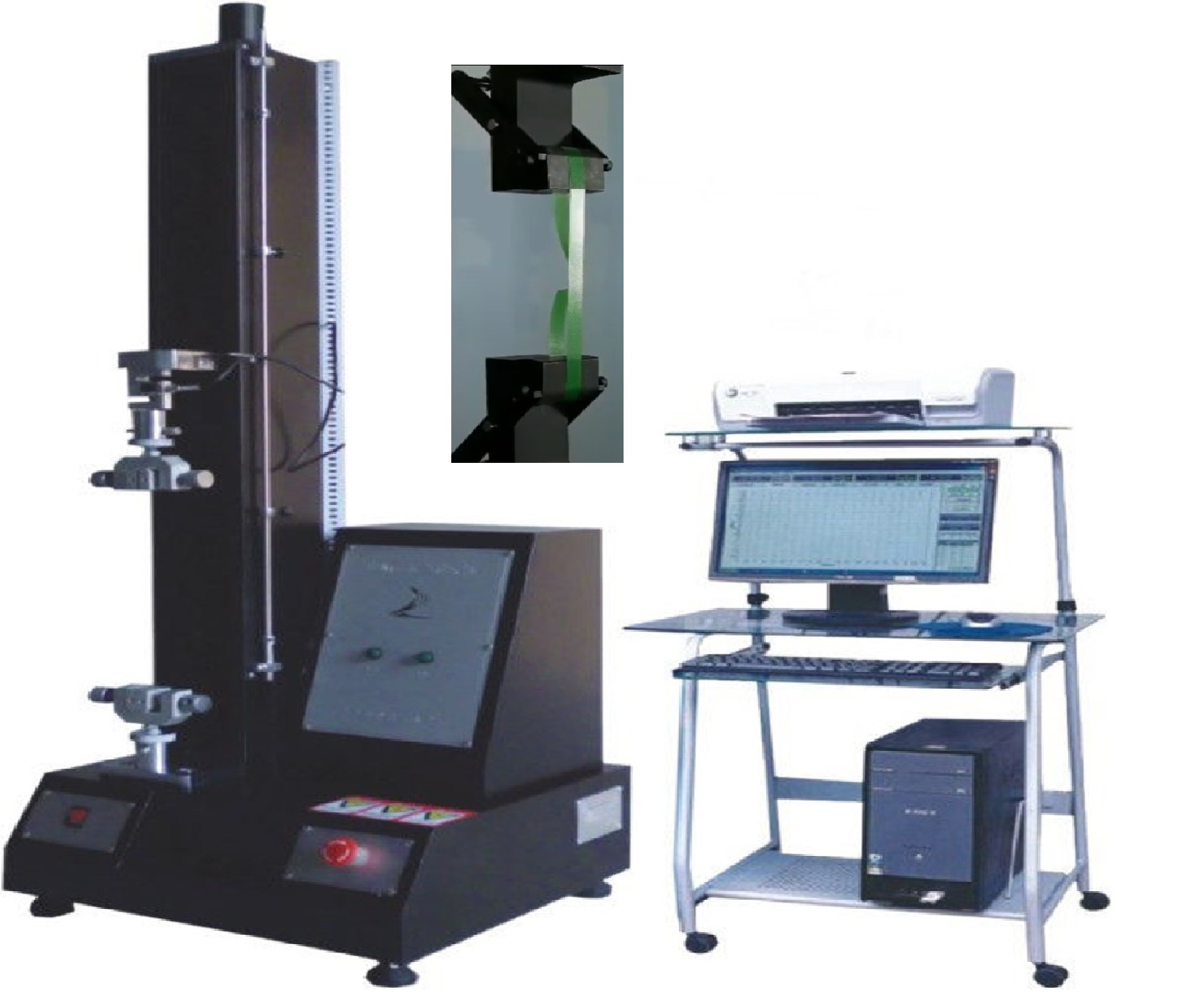

The manufacturing of CNIP Pet-strap will utilize high tensile Raw Virgin Flex, ensuring quality and durability. A systematic approach will be employed for testing and inspection, with break tests conducted at elongation rates ranging from one-fourth inch to 5 inches per minute to assess the material's strength and performance.

CNIP STRAP by CNIP India is a premium range of High Tensile PET Strap, crafted from meticulously sourced materials and produced under stringent standards, leveraging advanced technical expertise and a commitment to continuous research and innovation in manufacturing processes.